This is what Carl Friedrich von Weizsäcker said:

‘Research is the simple pleasure of finding something you didn’t know before’

We have also made research part of our work and are looking for ways to create something new. Especially with today’s accelerating digitalisation, it is important to do research and push boundaries. This is the only way to shape the future. Just look at the development in the automotive sector. Just a few years ago, vehicles had between 30 and 40 control units. Today, there are between 80 and 100 in a car – and the trend is rising.

It is precisely the complexity related to autonomous driving – the prevalence of a zero tolerance limit – that makes it necessary to test the ECUs in all relevant combinations and versions in a hardware setup. These tests are carried out in the vehicles themselves or in so-called test racks. However, since each hardware setup can only map one vehicle combination at a time, the increasing variety of vehicles results in an equally increasing number of test setups. The result is an enormous space requirement with correspondingly high acquisition and operating costs.

With the help of the VDI/VDE to the research project

On the basis of this, NgC GmbH decided to apply to the VDI/VDE/IT for funding for the planned carSIM project. This company supports SMEs in particular in the creation of research programmes.

The aim of the carSIM project was to create a digital solution (digital test track) in which all control units can be simulated and tested with regard to their functions and interactions. By means of virtualisation, it is possible to represent the multitude of ECUs in their versatile combinations and with every possible software version. The combinations would be both cost-efficient and available in a timely manner. Last but not least, in addition to the economic factor (acquisition costs and space requirements), the environmental factor is also a central starting point. After all, the HiL setups require enormous amounts of energy, which would grant a significantly better CO2 footprint through the digital solution. Environment and climate are more present than ever. Another advantage is the easy intervention in the virtual system. This makes it possible to easily make adjustments to the virtual hardware at any time and thus adapt it to the corresponding test scenarios or even the progress on the automotive market.

The application was successfully submitted and approved, as a result of which the research work began on 01.01.2020, in collaboration with our innovation location in Magdeburg.

Research work pays off

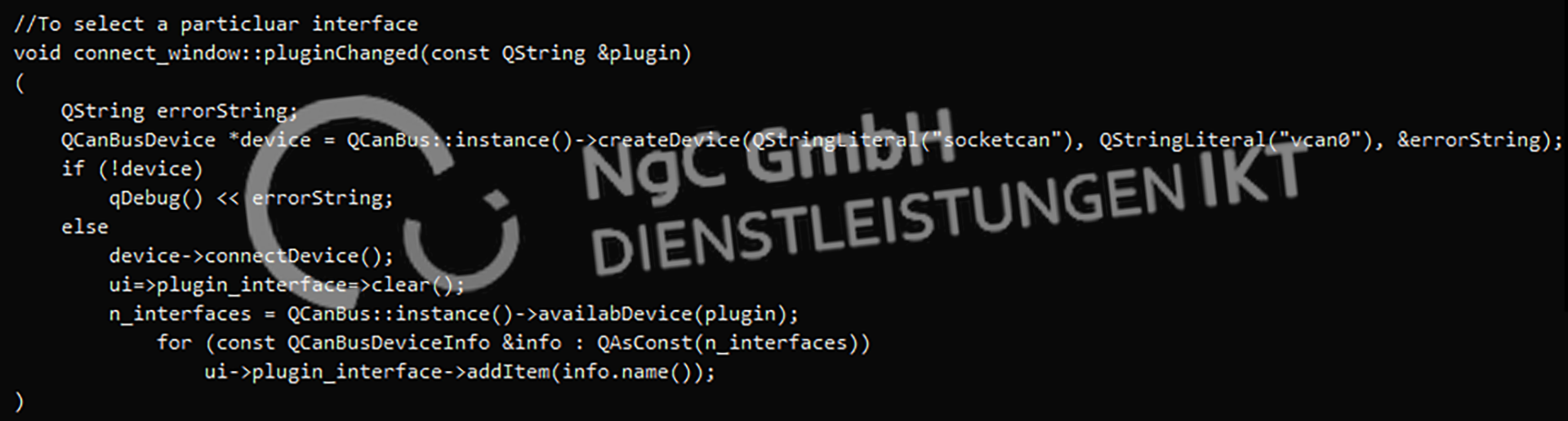

In the first approach, it was analysed and tested how the hardware could be converted into a digital solution. With the help of virtualisation software, a development environment was created in the first step that allowed free editing and adaptation of the virtual control unit. This created the starting point. During the development process at command level, it became clear that communication and functionality required visualisation, which is why a specially adapted Graphical User Interface (GUI) was designed for the project and programmed in parallel with the QT framework. With this interface, the communication between the virtual control unit and the environment can be shown. The analysed ECU was then virtualised using virtualisation software. This made it possible to anticipate future compatibility problems in terms of communication interfaces and transport protocols. All interfaces were implemented during the virtualisation process.

After completion of the SiL construction of the control unit including GUI, the communication of the digital system with the backend was enabled in the following development steps. The connection was initiated by the system itself. Subsequently, automatic authentication takes place at the backend. After successful connection and authentication, a function can be called up via the associated application, which is visible as a positive response both in the interface and in the app after a successful run.

Successful completion of the carSIM project

The entire system, which was previously combined in a HiL system, the so-called test rack, was transferred into a digital solution by the carSIM project. It is now possible to map any combination of control units and software versions and to test their functions.

It is also conceivable to use this XiL setup during the development phases in the automotive sector. In this way, tests with individual and newly developed control units can be carried out during development without having to have prototypes made in advance. Errors can thus be detected before production without incurring additional costs. The system makes it possible to make adjustments during the test scenarios until an appropriate solution is found. The project opens up a multitude of possibilities for the automotive sector, but technology and knowledge transfer to other areas such as robotics could also be adequate fields of application. One can see the limitless possibilities that arise from this project and the human mind alone sets limits to this, but together as a team these can be overcome and a future shaped in which we live.